Manufacturing Process

Manufacturing Process

FORGING

PVS Bearing use high quality Bearing Steel SAE 52100 / 100CR6 or Equivalent(Modified) Prime Steel of International Acceptability for manufacturing Bearing Rings.

SPHEROIDIZE ANNEALING

Forged Bearing Rings undergoes Spheroidize Annealing Process which improves Ductility and toughness with reduced Hardness and Strength to produce a definite Microstructure.

CNC MACHINING

After Spheroidize Annealing the Bearing Rings are sent for CNC turning process.Each Rings undergoes Dimensional & Visual Checking.

HEAT TREATMENT PROCESS

One of the Important Step for creating a highly durable & Long lasting Bearings is Heat Treatment Process.Our Heat treatment process consist of Hardening, Super Cooling and tempering which gives stabilized ring structure and increase the life span of bearings.

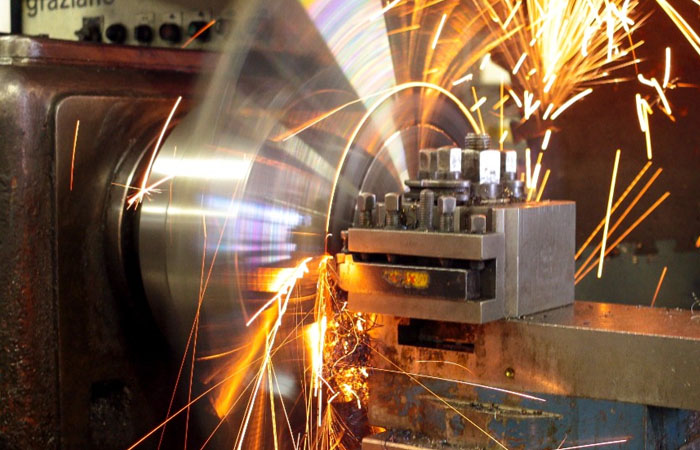

GRINDING

Grinding is the most important process of bearings.To achieve Accurate Dimensions in grinding process, PVS fully automatic machines are capable of manufacturing superior quality bearings under highly qualified engineer's team..

SUPER FINISHING

After Grinding Rings undergoes Super finish process on CNC Super Finish Machine which ensures best Roughness Values. We Control Roughness Values below 0.16 microns for Raceways & Rollers.

INSPECTION

Before assembling bearings, Each and every rings are checked visually and Size of all rings are checked by our engineers in our Inspection room. Only after passing the quality test, components are taken for assembling.

ASSEMBLY & PACKAGING

Our Assembly & packing department is fully automatic with a capacity of packing 6000 pieces per day.We ensure Export Oriented Packaging that Do not Damage the Products.